Analysis & Security

The IMV Quality System

Our Quality Assurance System is based on the articles, identified through an unambiguous alphanumeric code.

A Control Plan detailing all tests and measurements to be taken at all production steps is associated to each article code.

In full compliance with customers’ needs, I.M.V. S.p.A. can supply various certifications and report as required, for instance:

- PPAP documents;

- Inspection certificates;

- SPC process analysis;

- reliability test.

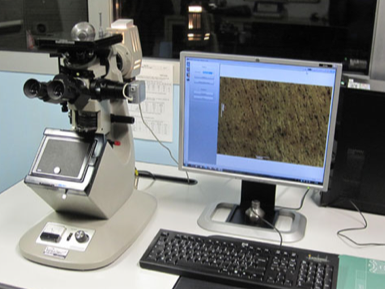

In-house test laboratory

The Quality Assurance/Quality Control department makes use of an equipped laboratory to verify the compliance of all the incoming and outgoing material with the required specifications.

The Quality laboratory is equipped with instruments to measure dimensional, mechanical and chemical characteristics:

- DEA coordinate measuring machine;

- Taylor-Hobson profilometer;

- Optical gage;

- HRB and HRC durometers;

- Metallurgical microscope;

- Micrometers, gauges, callipers (also certified);

- Spectrophotometer, for the burner caps’ coloring;

- Tensile testing machine.

How are the tests carried out?

I.M.V. S.p.A. performs controls directly at the production line using advanced instruments, as for instance three-dimensional artificial vision systems.

Each handling unit is univocally identified and associated to the additional production elements involved (material, process, machinery, workers), to ensure a total traceability. The respective records are stored into digital archives and kept into the system for at least 5 years.

Find out how we can help you

Contact

Via Feltrina, 24

Setteville (BL)

P.IVA e C.F. 00641570254