Production Capacity

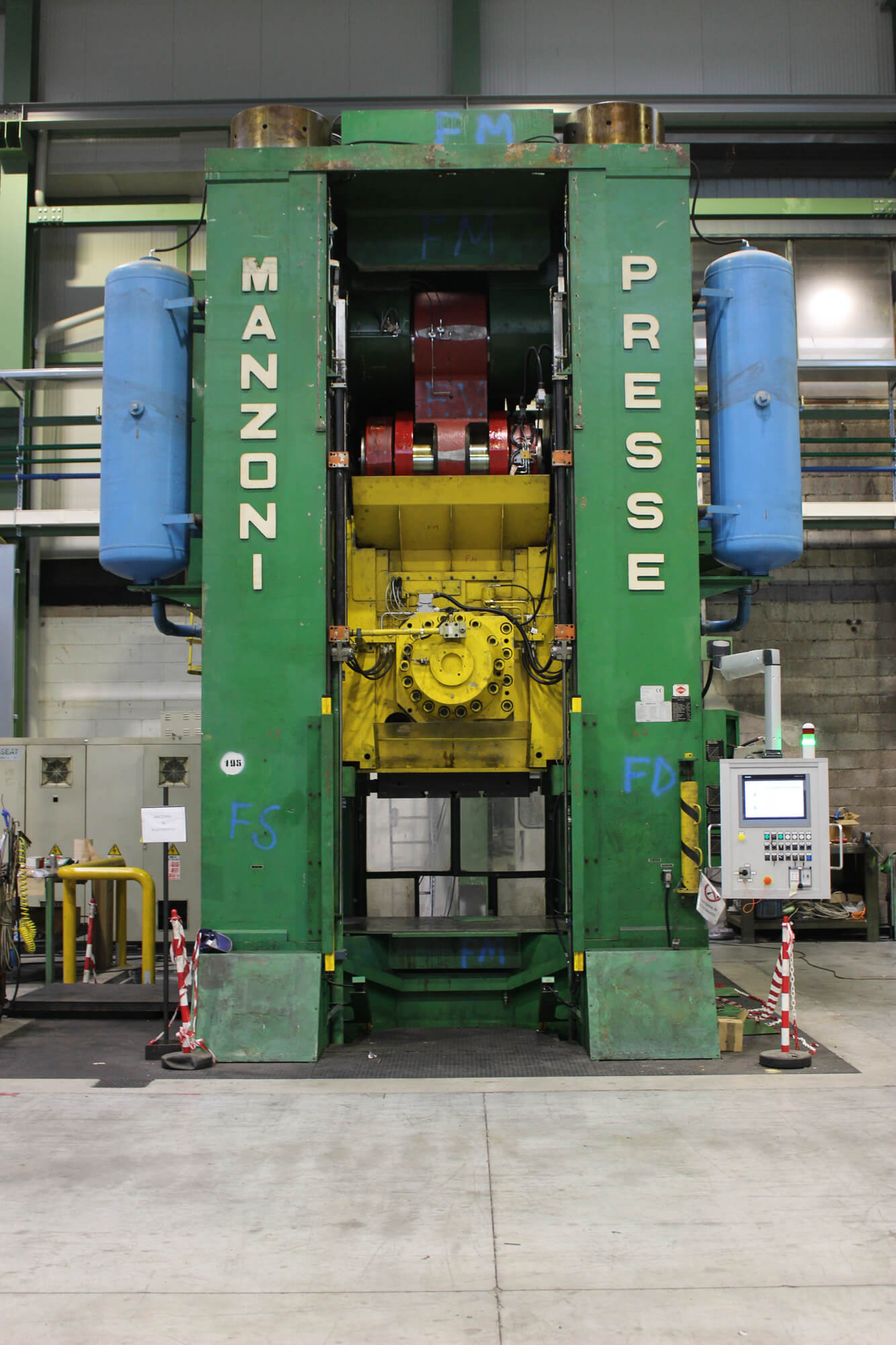

Production equipment at IMV SpA

4 Hydraulic presses (from 500 to 1250 tons), tended by transfer machines or robots, and equipped to process bar sections;

Mechanical toggle presses (from 500 to 4600 tons), tended by a coil-unwinding line, able to process sheet metal with thicknesses ranging from 1.5 to 8 mm;

4 Mechanical eccentric presses (from 200 to 300 tons) for processing sheet metal;

5 Screw presses with a screw diameter ranging from 160 to 320;

4 Mechanical toggle presses (from 1000 to 3600 tons) equipped to process bar sections;

1 Phosphatizing plant with screw conveyor;

3 High-speed cut-off machines for cutting bars with a diameter of up to 65 mm;

1 Bell furnace for heat treating raw material;

2 Okuma lathes for the secondary machining of forged parts;

2 Mori Seky lathes for the secondary machining of forged parts.

Equipment for the production of moulds at IMV SpA

Wire and die-sinking EDM machines;

Flat-surface and cylindrical grinding machines;

Okuma lathes for machining moulds even after they have hardened;

High-speed, 3- and 5-axis Okuma machining centres.

Mold Warehouse

Raw Material Warehouse

PARTNER IMV SpA

Production equipment at Essegiemme srl

Washing machine;

Sandblasting machine;

An enamelling line with automatic loading and a firing oven (mass production);

Manual spray booth (small series).

Contact

Via Feltrina, 24

Setteville (BL)

P.IVA e C.F. 00641570254